Introduction

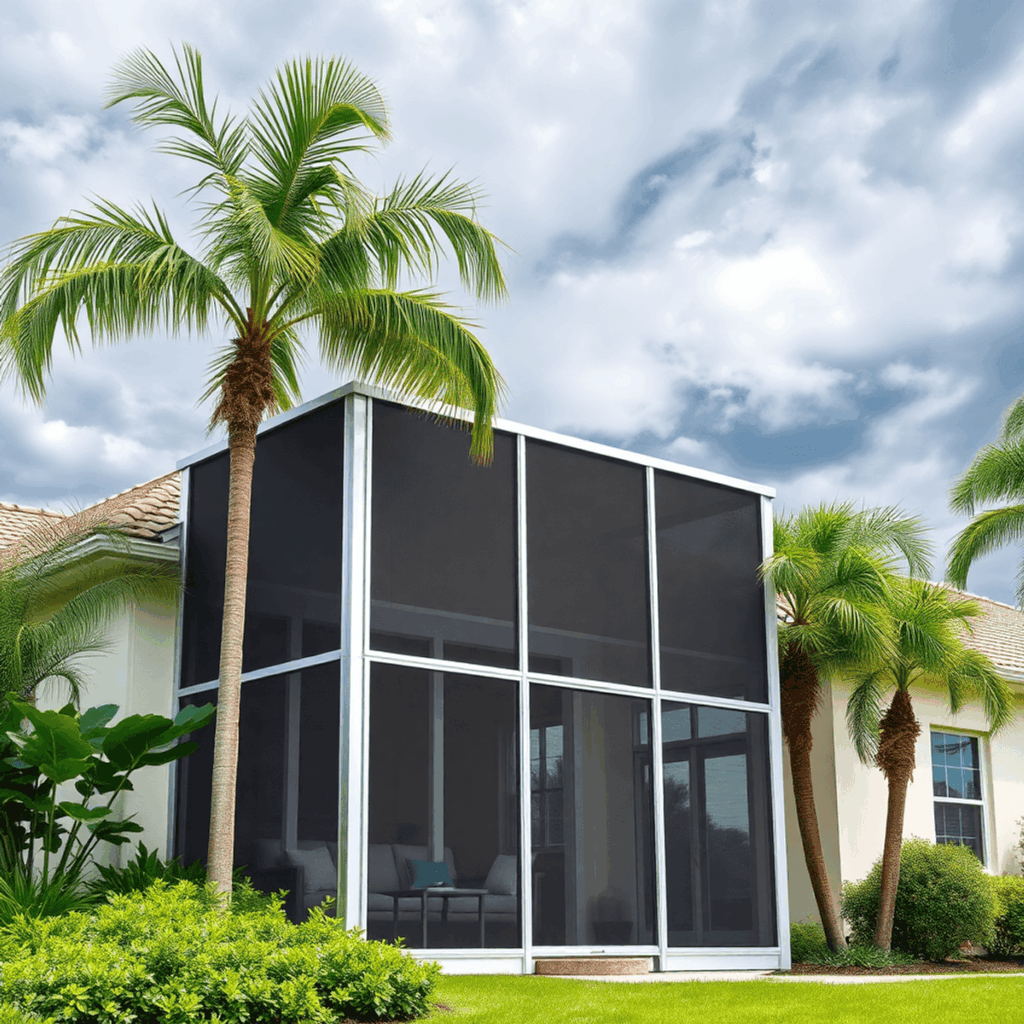

You’ve probably noticed them everywhere across Florida—those beautiful screen enclosures transforming ordinary patios into comfortable outdoor living spaces. These structures have become a staple in Florida homes, and for good reason. They keep bugs out while letting fresh air in, protect your outdoor furniture from the elements, and create an additional living area where you can enjoy Florida’s beautiful weather year-round.

But here’s the reality: Florida screen enclosures face some of the harshest weather conditions in the United States.

Living in Florida means dealing with tropical storms, hurricanes, and intense wind events that can turn your beloved screen enclosure into a pile of twisted aluminum and torn screening in a matter of hours. You’ve likely seen the aftermath—neighbors’ enclosures crumpled like aluminum foil, screens shredded, and structural components scattered across yards after a major storm passes through.

The structural integrity of your screen enclosure isn’t just about aesthetics or property value. It’s about safety, protection, and avoiding the financial burden of repeated repairs or complete replacements. When a screen enclosure fails during a storm, the damage doesn’t stop there. Flying debris from a collapsed enclosure can damage your home’s exterior, break windows, or even injure someone. The costs add up quickly, and insurance claims become a headache you didn’t plan for.

Understanding why Florida screen enclosures fail during storms is your first line of defense against these costly disasters.

You need to know what makes one enclosure crumble while another withstands the same hurricane-force winds. The difference often comes down to construction quality, materials used, adherence to building codes, and proper maintenance. Many homeowners discover too late that their screen enclosure—perhaps installed decades ago or built by contractors cutting corners—simply wasn’t designed to handle the storm forces common in Southwest Florida and other hurricane-prone regions.

This guide walks you through the critical factors that determine whether your screen enclosure survives the next big storm or becomes another statistic of storm damage. You’ll learn about the common construction flaws that lead to failure, modern techniques that prevent it, and practical steps you can take right now to protect your investment.

For those looking to choose the ideal screen enclosure for their home or seeking advice on keeping their Florida screen enclosure clean and maintained, this guide will also provide valuable insights into various screen enclosure options available in the market.

1. Common Causes of Screen Enclosure Failures in Florida Storms

When you walk through Southwest Florida neighborhoods after a major storm, you’ll notice a pattern: some screen enclosures stand intact while others lie twisted and torn. The difference isn’t luck—it’s construction quality and design choices that determine whether your investment survives hurricane-force winds or becomes another casualty of storm season.

Lightweight Aluminum Frames: The Weak Link

Screen enclosures built during the 1990s and early 2000s often used aluminum frames that simply weren’t engineered for Florida’s extreme weather conditions. These lightweight aluminum frames prioritized cost savings over structural integrity, resulting in catastrophic failures when winds exceeded 70-80 mph.

You can identify these vulnerable structures by their thin-walled aluminum posts and beams, typically measuring less than 0.065 inches in thickness. During storms, these frames exhibit predictable failure patterns:

- Bending at mid-span points where horizontal beams lack adequate support

- Snapping at corner connections where stress concentrates during wind gusts

- Buckling of vertical posts when lateral wind forces exceed the frame’s load capacity

- Twisting of roof members that weren’t designed to resist rotational forces

The aluminum frame weakness becomes especially apparent in older enclosures that have experienced years of thermal expansion and contraction, which gradually weakens the metal’s structural properties. Many homeowners don’t realize their enclosure has become compromised until a storm exposes these hidden vulnerabilities.

Mechanical Fasteners: A Recipe for Disaster

Walk up to an older screen enclosure and examine the corners closely. You’ll likely see bolts, brackets, and screws holding the frame together—these mechanical connections represent one of the most significant screen enclosure failure causes during severe weather events.

Bolted connections create several problems:

- Stress concentration: Unlike welded joints that distribute forces across the entire connection area, bolts create pressure points where the fastener contacts the aluminum. When wind loads increase, these concentrated stress points become failure initiation sites.

- Loosening over time: Florida’s temperature fluctuations cause aluminum to expand and contract daily. This constant movement gradually loosens mechanical fasteners, creating gaps and reducing the connection’s load-bearing capacity. You might not notice this degradation until wind forces test the weakened joints.

- Corrosion at connection points: Moisture infiltration around bolt holes accelerates galvanic corrosion, especially when dissimilar metals contact each other. The resulting corrosion weakens both the fastener and the surrounding aluminum, compromising structural integrity long before visible damage appears.

- Limited load transfer: Mechanical connections can only transfer forces through the small contact area of the fastener. During storms, when wind loads spike suddenly, these limited connection points cannot redistribute stress effectively throughout the structure.

Anchoring Issues: The Foundation of Failure

The most overlooked aspect of screen enclosure construction involves what you can’t see—the anchoring system that connects the structure to your home’s foundation. Anchoring issues account for a substantial percentage of complete enclosure collapses during major hurricanes.

Inadequate footings plague many older installations. Contractors who cut corners often used:

- Shallow concrete footings extending only 12-18 inches below grade

- Undersized anchor bolts rated for normal wind loads rather than hurricane conditions

- Insufficient embedment depth for anchor bolts, allowing them to pull free under stress

- Missing or improperly installed expansion anchors in existing concrete slabs

2. The Importance of Florida Building Codes and Wind Zone Ratings

The Florida Building Code sets specific rules for building screen enclosures based on where your property is located and how much severe weather it might be exposed to. By understanding these rules, you can determine if your enclosure meets the current safety standards.

Understanding Wind Zone Classifications

Florida has divided the state into different wind zones that determine the minimum design requirements for outdoor structures. These classifications take into account two main factors:

- Distance from the coastline – Properties closer to the ocean experience stronger winds during hurricanes.

- Elevation above sea level – Areas that are lower in height have different wind pressures compared to higher locations.

The wind zone ratings range from basic inland classifications that require structures to withstand winds of 130 mph, up to coastal high-velocity hurricane zones (HVHZ) where enclosures must be able to resist sustained winds of 180 mph or more. Southwest Florida, where Precision Aluminum & Remodeling operates, falls into some of the most strict wind zone categories because it is located along the Gulf Coast.

You can find out what wind zone your property falls under by checking the wind speed maps in the Florida Building Code or by asking your local building department for this information. This classification directly affects every aspect of how your screen enclosure is designed, including the thickness of the aluminum used and how far apart the support posts are spaced.

The Gap Between Old and New Standards

Screen enclosures built before the early 2000s usually do not meet the current requirements set by the Florida Building Code. After Hurricane Andrew in 1992, the state made significant improvements to its building standards, and then made further changes after the devastating hurricane season in 2004.

Enclosures built during the 1990s and early 2000s often have:

- Aluminum framing that is too thin to meet today’s wind load calculations

- Anchor systems designed for lower wind speed limits

- Spacing between structural supports that exceeds current maximum allowances

- Roof systems without proper bracing for uplift forces

The updates to the code did not just change numbers – they completely transformed how engineers approach designing structures that can withstand hurricanes. Modern standards take into account factors such as differences in wind pressure, debris impact scenarios, and long periods of exposure to high winds, which older designs simply did not consider.

If you have a screen enclosure that was built before these major code changes, you are essentially relying on a structure that was designed for weather conditions that no longer match Florida’s documented storm patterns. The building department will not require you to upgrade an existing enclosure unless you are making significant changes, but there will still be structural weaknesses.

What Modern Codes Require

The current provisions in the Florida Building Code require specific construction elements that greatly enhance resistance against storms. These requirements are not optional – they are minimum standards that contractors must adhere to for installations that require permits.

-

Heavier-gauge aluminum forms the foundation of code-compliant enclosures. Where older structures used thin-walled tubing that could bend under moderate stress, modern standards specify thicker aluminum profiles with greater cross-sectional strength. The exact gauge requirements vary by wind zone, but you’ll typically see aluminum that’s 30-50% thicker than what contractors used two decades ago.

-

Reinforced beams appear at critical load-bearing points throughout the structure. The code identifies specific locations—such as roof ridge lines, eave connections, and corner posts—where standard aluminum profiles aren’t sufficient. These areas receive additional reinforcement through doubled beams, steel inserts, or specially engineered aluminum sections with enhanced strength properties.

-

Upgraded anchors connect your enclosure to the concrete foundation with far greater holding power than older installations. Modern anchoring systems use deeper embedment into the concrete slab (typically 4-6 inches versus the 2-3 inches common in older installations)

3. Modern Construction Techniques That Prevent Failure

The difference between a screen enclosure that survives a hurricane and one that becomes debris lies in the construction methods used during installation. You can’t rely on outdated techniques if you want your investment to withstand Florida’s most severe weather events.

Structural-Grade Aluminum: The Foundation of Storm Resistance

Standard residential-grade aluminum simply doesn’t cut it when you’re facing 100+ mph winds. Structural-grade aluminum uses thicker walls and denser alloy compositions specifically engineered for load-bearing applications. Where older enclosures might use aluminum extrusions with wall thicknesses of 0.050 inches or less, modern storm-resistant designs incorporate beams measuring 0.080 to 0.125 inches thick.

This increased material density provides several critical advantages:

- Higher load capacity – Structural-grade beams can handle significantly greater wind pressures without deflecting or bending

- Reduced flex during storms – Thicker walls mean less movement, which translates to less stress on connection points

- Extended service life – Heavier gauge aluminum resists fatigue from repeated wind loading over decades

You’ll notice the weight difference immediately when comparing structural-grade components to standard materials. A 10-foot beam section might weigh 30-40% more, but that extra mass represents the engineering margin that keeps your enclosure standing when your neighbors’ structures fail.

Welded Corners: Eliminating the Weakest Link

Mechanical fasteners—bolts, screws, and brackets—create inherent weak points in any structure. These connections loosen over time due to thermal expansion, vibration, and repeated stress cycles. When hurricane-force winds hit, these loosened connections become catastrophic failure points.

Fully welded corners change this equation entirely. The welding process fuses aluminum components at the molecular level, creating a single continuous piece rather than separate parts held together by hardware. You get uniform stress distribution across the entire joint instead of concentrated pressure on individual bolts.

The engineering benefits include:

- No loosening over time – Welded joints maintain their integrity indefinitely without requiring retightening

- 360-degree load distribution – Forces spread evenly around the entire connection rather than focusing on bolt holes

- Elimination of stress concentrations – Drilled holes for mechanical fasteners create weak spots where cracks can initiate

Professional contractors who understand why most Florida screen enclosures fail in storms—and how to avoid it prioritize welded construction. You’ll pay slightly more upfront for the additional fabrication work, but you’re buying peace of mind that your enclosure won’t separate at the corners during the next major storm.

Stainless Steel Hardware: Corrosion-Resistant Strength

Florida’s salt air, humidity, and frequent rain create an aggressively corrosive environment. Standard zinc-plated or galvanized hardware deteriorates within 5-10 years, leaving you with weakened connection points precisely when you need maximum strength.

Stainless steel hardware resists this corrosion indefinitely. Grade 304 or 316 stainless steel fasteners maintain their full tensile strength even after decades of exposure to coastal conditions. You’re looking at hardware that can still provide 70,000+ PSI of holding force when a Category 4 hurricane makes landfall.

The investment in stainless steel extends beyond just fasteners:

- Through-bolts – Stainless steel bolts that pass completely through structural members provide superior clamping force

- Anchor plates – Larger steel plates embedded in concrete footers

4. Advanced Screen Materials for Storm Resistance

The aluminum framework is important, but you also need to pay attention to what covers that frame. Traditional screen materials have been the weak point of many Florida enclosures during storms. You’ve probably seen the damage—screens torn apart like tissue paper, leaving the whole structure exposed to winds it wasn’t built to withstand on its own.

High-wind screen mesh is a major improvement over regular screening materials. These specialized screens have tighter weaves and stronger synthetic fibers designed specifically for Florida’s tough weather conditions. When you’re choosing materials for your enclosure, it’s crucial to understand the significant difference between standard 18×14 mesh and the newer high-performance options available today.

Wind Rating Specifications That Actually Matter

Standard screening usually fails when winds reach speeds of 60-75 mph. On the other hand, tear-resistant screens rated for extreme conditions can endure sustained winds up to 110 mph—the difference between minor repairs and complete reconstruction after a hurricane passes through Southwest Florida. These are materials that have undergone extensive testing in wind tunnel facilities, not just theoretical calculations on paper.

The finer thread mesh construction serves multiple purposes beyond simple durability:

- Reduced wind penetration through the screening material itself

- Lower stress transfer to the aluminum frame during wind events

- Maintained structural integrity even when debris impacts occur

- Extended lifespan under constant UV exposure and salt air conditions

How Upgraded Materials Change Wind Load Dynamics

Here’s what most homeowners don’t realize: your screen material directly affects how much force transfers to your enclosure’s frame. Standard screens act like sails during storms, catching wind and creating enormous pressure against every beam, post, and connection point. You’re essentially asking your aluminum structure to fight against forces it wasn’t designed to handle.

Upgraded screening materials change this equation entirely. The tighter weave allows wind to pass through more efficiently rather than catching and holding it. You reduce the overall wind load on your structure by 30-40% compared to traditional materials—that’s the difference between a frame that bends and one that stands firm.

Polyester-based high-wind screens offer superior tensile strength compared to fiberglass alternatives. When you’re investing in a screen enclosure that needs to survive multiple hurricane seasons, you want materials that maintain their structural properties year after year. Fiberglass degrades under UV exposure, becoming brittle and prone to tearing. Polyester formulations resist this degradation while providing the flexibility needed to absorb impact without catastrophic failure.

The Physics of Screen Performance During Storms

Think about how your enclosure behaves during a storm. Wind doesn’t hit uniformly—it creates pressure differences, suction forces, and turbulent flows around your structure. Your screening material needs to handle all these dynamic forces at once. Finer mesh screens distribute these forces more evenly across the material rather than concentrating stress at weak points.

You’ll find that tear-resistant screens incorporate reinforced edges and corners where stress naturally concentrates. These reinforcements prevent the cascading failures you see with standard materials, where a small tear rapidly expands into complete panel failure. The screen stays intact, keeping your frame protected from the full force of wind.

Balancing Visibility and Protection

Some homeowners worry that finer mesh means reduced visibility or airflow. Modern high-wind screen mesh addresses these concerns through advanced manufacturing techniques. You get screens that maintain 70-80% visibility while providing superior storm protection. The slightly tighter weave actually improves insect protection without creating the “dark” feeling some older fine-mesh products produced.

Airflow remains adequate for comfortable outdoor living during normal conditions.

5. Maintenance Practices to Extend Lifespan and Storm Durability

Your screen enclosure won’t maintain its storm resistance on its own. Even the most expertly constructed enclosure with premium materials needs consistent attention to perform when hurricane-force winds arrive. I’ve seen too many homeowners invest thousands in quality installations only to skip basic screen enclosure maintenance, leaving their structures vulnerable when storms hit.

Critical Inspection Points for Screen Enclosures

Fastener inspection should be your first priority during any maintenance check. You need to examine every visible bolt, screw, and bracket connection throughout your enclosure. Look for:

- Loose or missing fasteners that create weak points in the structure

- Rust or corrosion around connection points indicating moisture penetration

- Stripped screw heads that won’t hold under stress

- Gaps between components where fasteners have backed out over time

Brackets deserve special attention because they’re often the first components to fail during high winds. Run your hand along each bracket connection—you shouldn’t feel any movement or play. If a bracket shifts even slightly when you apply pressure, it needs immediate tightening or replacement.

Welds require a different inspection approach. You’re looking for cracks, separation, or discoloration around welded corners and joints. A quality weld should appear uniform without gaps or rough spots. Any crack in a weld, no matter how small, compromises the structural integrity of that connection point.

Frame components need visual and physical assessment. Check aluminum beams for:

- Bending or warping that indicates previous stress damage

- Dents that weaken the structural capacity

- Corrosion or pitting on the aluminum surface

- Separation between frame members and posts

Seasonal Maintenance Schedule for Hurricane-Prone Areas

Living in Southwest Florida means you can’t treat screen enclosure maintenance as an annual task. You need a structured schedule that accounts for our intense storm season and year-round weather exposure.

Pre-Hurricane Season (April-May)

This is your most critical maintenance window. You want to identify and fix any issues before June 1st when hurricane season officially begins. Schedule a comprehensive inspection that covers:

- Complete fastener inspection and tightening of all connections

- Detailed examination of all welds and joints

- Assessment of screen material for tears, holes, or excessive wear

- Verification that all bracing remains secure and properly positioned

- Check of foundation anchors and footings for any movement or deterioration

In addition to these tasks, it’s also wise to install hurricane shutters during this period as an extra layer of protection.

Mid-Season Check (August-September)

Peak hurricane season demands another thorough review. You’ve likely experienced several storms by this point, even if they weren’t direct hits. Wind, rain, and debris take their toll. Repeat your fastener inspection, paying extra attention to any areas that showed minor concerns during your spring check.

Post-Season Evaluation (November-December)

After hurricane season ends, you need to document any damage or wear that occurred. This assessment helps you plan repairs during the calmer winter months and ensures you’re not starting the next season with compromised components.

Quarterly Quick Checks

Between your major seasonal inspections, perform brief monthly walk-throughs. You’re not doing deep maintenance—just looking for obvious problems like:

- New tears in screening material

- Visible damage from falling branches or debris

- Standing water or drainage issues around footings

- Any structural changes or shifts you can see

6. Choosing a Trusted Contractor for Storm-Resistant Enclosure Installation

The quality of your screen enclosure installation directly determines how well it will perform when hurricane-force winds arrive. You can specify the best materials and construction methods, but if the contractor lacks experience or cuts corners during installation, your enclosure remains vulnerable to storm damage.

Experience Matters in Hurricane-Prone Regions

A reliable contractor Cape Coral FL homeowners can trust brings decades of hands-on knowledge about what works—and what fails—in Florida’s extreme weather conditions. Precision Aluminum & Remodeling has spent over 30 years installing and repairing screen enclosures throughout Southwest Florida, witnessing firsthand which construction techniques withstand Category 4 hurricanes and which crumble under pressure.

This extensive experience translates into practical advantages for you:

- Understanding of local soil conditions that affect footing depth and anchor placement

- Knowledge of microclimates within Southwest Florida that influence wind load calculations

- Familiarity with common failure points specific to coastal and inland properties

- Relationships with suppliers providing genuine structural-grade materials rather than inferior substitutes

You benefit from this accumulated wisdom every time an experienced contractor makes a decision about your enclosure—from the initial design phase through the final inspection.

The Value of Proper Licensing and Insurance

A licensed aluminum contractor SWFL residents hire demonstrates commitment to professional standards and accountability. Licensing requirements in Florida mandate specific training, testing, and ongoing education about building codes and safety practices. You gain protection when working with licensed professionals because they understand the legal requirements for wind-resistant construction.

Insurance coverage provides another critical layer of protection. When contractors carry comprehensive liability and workers’ compensation insurance, you avoid financial exposure if accidents occur on your property. Precision Aluminum & Remodeling maintains full licensing and insurance, giving you peace of mind throughout the installation process.

Family-Owned Businesses and Long-Term Accountability

Veteran-owned and family-owned businesses operate with a different mindset than transient contractors who move from market to market. Precision Aluminum & Remodeling’s multi-generational involvement—with Harold, his son, grandson, and great-grandson all participating in the business—creates accountability that extends beyond a single transaction.

You’re not just another job number when you work with a family business that has served Southwest Florida since 1980. Your satisfaction directly impacts their reputation in the community where they live and raise their families. This local connection motivates them to:

- Stand behind their work for years after installation

- Respond quickly when you need service or have questions

- Maintain relationships with local building inspectors and code officials

- Invest in ongoing training for their installation teams

Specialized Knowledge of Florida’s Weather Challenges

Generic contractors who work across multiple states often lack the specialized understanding of Florida’s unique storm patterns and building requirements. You need someone who knows the difference between wind zone requirements in Cape Coral versus inland communities, who understands how saltwater corrosion affects coastal installations differently than properties five miles inland.

A contractor familiar with Why Most Florida Screen Enclosures Fail in Storms—And How to Avoid It brings this specialized knowledge to your project. They’ve seen the aftermath of Hurricane Irma, Hurricane Ian, and countless tropical storms. They know which shortcuts lead to failures and which investments in quality materials and construction techniques provide genuine protection.

Showroom Access and Transparent Communication

The availability of a physical showroom at 4417 SE 16th PL, Units 14 & 16 in Cape Coral demonstrates a contractor’s commitment to transparency. It allows you to:

- See materials up close: Instead of relying solely on brochures or online images, visiting the showroom lets you touch and feel the actual products being used in your project.

- Ask questions directly: Face-to-face interactions with knowledgeable staff members provide an opportunity for clarification on any doubts or concerns you may have.

- Compare options easily: With various displays showcasing different designs, colors, and finishes side by side, making decisions becomes more efficient.

- Understand pricing better: Having access to pricing information for different choices helps set realistic expectations regarding costs associated with upgrades or customizations.

By choosing a contractor who prioritizes open communication through both digital channels (emails/calls) as well as personal visits (showroom), you’re ensuring that all parties involved are on the same page throughout every stage of the project—from initial discussions about ideas/preferences down until final walkthroughs post-installation where feedback is exchanged freely without hesitation or ambiguity whatsoever!

7. Preparing Your Existing Screen Enclosure for Hurricane Season

You don’t need to wait until your screen enclosure fails to take action. If you already have an enclosure installed, a proactive hurricane preparedness evaluation can identify vulnerabilities before the next storm season arrives. This assessment process involves a thorough inspection of your structure’s current condition and determines which components need attention.

Professional Structural Condition Assessments

Precision Aluminum & Remodeling offers comprehensive pre-season evaluations that examine every critical aspect of your existing screen enclosure. During these assessments, experienced technicians inspect:

- Frame integrity – checking for corrosion, stress fractures, or weakening in aluminum beams

- Connection points – evaluating bolts, brackets, and welds for signs of loosening or deterioration

- Foundation anchoring – verifying that footings remain secure and properly embedded

- Screen material condition – identifying tears, excessive wear, or outdated mesh that won’t withstand high winds

- Roof structure – examining support beams and bracing for adequate wind resistance

- Hardware quality – assessing whether fasteners show rust or degradation

These evaluations typically take place in late spring or early summer, giving you adequate time to complete necessary repairs before hurricane season peaks from August through October. You receive a detailed report outlining specific concerns and recommended actions ranked by priority.

Strategic Reinforcement Options

Based on assessment findings, contractors can implement targeted upgrades to strengthen your existing enclosure without requiring complete replacement. Common reinforcement strategies include:

Adding K-Bracing Systems

If your enclosure lacks adequate bracing, installing heavy-duty K-braces on roof sections and wall panels significantly improves wind resistance. These diagonal supports connect to the frame using stainless steel through-bolts, creating a triangulated structure that distributes wind forces more effectively than unbraced designs.

Upgrading Mechanical Connections

Older enclosures with bolt-and-bracket assemblies benefit from reinforced connection hardware. Contractors can replace corroded or undersized fasteners with marine-grade stainless steel components rated for coastal environments. In some cases, adding welded reinforcement plates at critical joints provides the stress distribution benefits of fully welded construction without dismantling the entire structure.

Strengthening Foundation Anchors

Shallow or deteriorating footings represent a serious vulnerability. Reinforcement options include:

- Installing deeper anchor bolts into existing concrete footings

- Adding supplementary concrete piers at strategic support points

- Replacing compromised footings entirely with code-compliant foundations

- Integrating tie-down systems that connect the frame directly to ground anchors

Screen Material Replacement

Switching from standard screening to wind-rated mesh materials reduces the sail effect during storms. You can upgrade to finer thread screens rated for winds up to 110 mph, which maintain visibility while dramatically decreasing the wind load your frame must withstand. This single upgrade often prevents the cascading failure that occurs when torn screens allow wind to pressurize the enclosure interior.

To ensure you have the right screen enclosure for your home that can withstand such conditions, consider exploring different types of screen enclosures available in the market.

Structural Member Reinforcement

Thin or damaged aluminum beams can be reinforced with additional structural members installed alongside existing frames. This sister-beam technique doubles the load-bearing capacity without requiring removal of the original structure. Contractors may also recommend replacing severely compromised sections with heavier-gauge aluminum that meets current building code specifications.

Timing Your Hurricane Preparedness Evaluation

You should schedule your assessment at least three months before

Conclusion

Durable Florida screen enclosures don’t happen by accident. They’re the result of deliberate design choices, quality materials, and construction methods that acknowledge the reality of living in a hurricane-prone region. You’ve seen throughout this article why most enclosures fail—weak aluminum frames, mechanical connections that loosen, inadequate anchoring, and materials that can’t withstand Florida’s extreme weather conditions.

The difference between an enclosure that collapses during the next storm and one that stands strong comes down to three critical factors:

- Engineering that meets or exceeds current Florida building codes for your specific wind zone

- Construction techniques that prioritize structural-grade aluminum, welded corners, stainless steel hardware, and proper bracing systems

- Ongoing maintenance that catches potential problems before they become catastrophic failures

You can’t control when the next hurricane will hit Southwest Florida. You can control how prepared your property is when it does.

If you’re building a new storm-proof lanai installation in Cape Coral, FL or surrounding areas, partnering with experienced contractors who understand local weather challenges makes all the difference. Precision Aluminum & Remodeling brings over 30 years of expertise to every project, combining veteran-owned reliability with family business values that have served Southwest Florida since 1980.

Their licensed and insured team doesn’t just install screen enclosures—they engineer solutions specifically designed for the unique demands of this region. From structural assessments to complete installations using reinforced materials and modern construction techniques, you’re working with professionals who’ve weathered decades of Florida storms themselves.

Understanding why most Florida screen enclosures fail in storms—and how to avoid it isn’t just about knowing what goes wrong. It’s about taking action before the next storm warning appears on your weather app. Whether you need a comprehensive structural evaluation of your existing enclosure or you’re ready to invest in a new installation built to withstand 110+ mph winds, the time to act is now—not when you’re watching storm trackers approach the Gulf Coast.

Visit Precision Aluminum & Remodeling to schedule your expert consultation or request a free estimate. Their showroom at 4417 SE 16th PL, Units 14 & 16 in Cape Coral welcomes homeowners who want to see quality materials and construction methods firsthand. You’ll work directly with Harold and his team—multiple generations of the founding family who’ve built their reputation on honest, ethical service and fast turnaround times.

Protecting your outdoor living space from storm damage isn’t an expense. It’s an investment in your property’s value, your family’s safety, and your peace of mind when hurricane season arrives. The question isn’t whether you can afford to build or upgrade to a storm-resistant enclosure—it’s whether you can afford not to.

To ensure the longevity and durability of your screen enclosures, regular cleaning and maintenance are essential. Moreover, understanding the different types of screen enclosures and their costs can help you make informed decisions when investing in such structures.

FAQs (Frequently Asked Questions)

Why do most Florida screen enclosures fail during storms?

Most Florida screen enclosures fail in storms due to factors like lightweight aluminum frames prone to bending or snapping, mechanical connections loosening over time, inadequate footings and shallow anchoring systems, and thin screen mesh materials that tear easily under high wind loads.

How do Florida Building Codes and wind zone ratings impact screen enclosure durability?

Florida Building Codes classify regions based on wind zone ratings reflecting coastal proximity and storm exposure. Older enclosures often don’t meet updated code requirements that mandate heavier-gauge aluminum, reinforced beams, upgraded anchors, and additional bracing to ensure hurricane-resistant design and improved storm durability.

What modern construction techniques help prevent screen enclosure failure in storms?

Modern techniques include using structural-grade aluminum with thicker reinforced beams, fully welded corners to evenly distribute stress, stainless steel hardware for corrosion resistance and strength, and heavy-duty roof and wall K-braces connected with stainless steel through-bolts for superior wind bracing.

Which advanced screen materials offer better storm resistance for Florida enclosures?

High-wind screen meshes made from finer thread materials rated for extreme wind resistance up to 110 mph significantly reduce the risk of tearing. Upgraded screening materials also decrease overall wind load on the enclosure structure during storms, enhancing durability.

What maintenance practices can extend the lifespan and storm durability of Florida screen enclosures?

Regular inspections focusing on fasteners, brackets, welds, and frame components are essential to detect wear or loosening early. Homeowners in hurricane-prone areas should follow recommended maintenance schedules to ensure structural integrity before storm seasons.

Why is choosing a trusted contractor important for installing storm-resistant screen enclosures in Florida?

Hiring experienced local contractors like Precision Aluminum & Remodeling ensures installation by licensed professionals familiar with Florida’s unique weather challenges. Benefits include expertise from over 30 years in remodeling & aluminum services, use of quality materials and construction methods, and assurance of durable, storm-proof lanai installations tailored for Southwest Florida conditions.